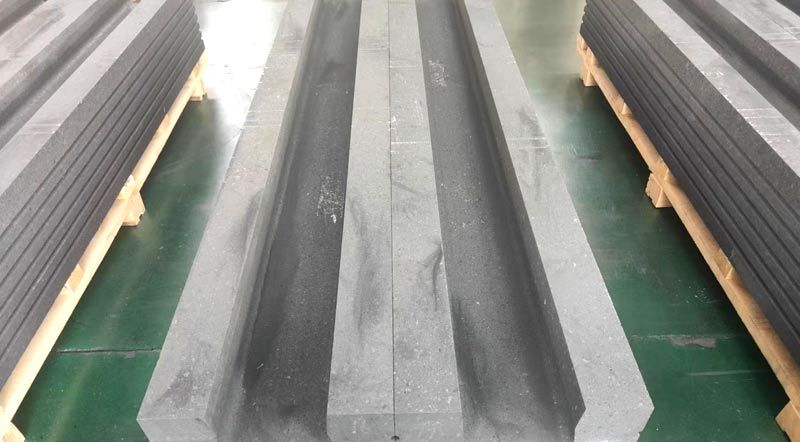

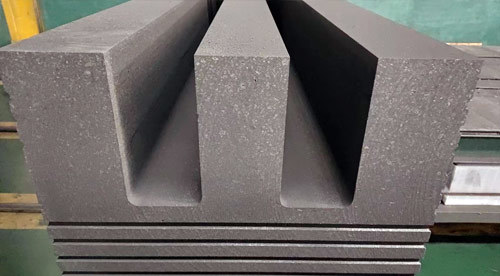

Graphitized cathode carbon block

Classification:

- Description

-

Cathode carbon blocks are produced by calcination, molding, roasting, impregnation, graphitization and machining processes with high-quality calcined petroleum coke as the main raw material. Graphitized cathode can effectively reduce the pressure drop at the bottom of the furnace, the current efficiency is high, the power consumption is significantly reduced, the sodium corrosion resistance is good, can improve the tank life, reduce the number of electrolytic cell overhaul and the number of roasting start-up, reduce environmental pollution, and is conducive to greatly strengthen the current, improve production capacity. The company's products are mainly sold to the country's major, medium and small aluminum group.

Molding workshop: the use of independent research and development of vacuum vibration molding machine. The products produced have good homogeneity, high density and strength, and the density of graphitized carbon blocks can be ≥ 1.65g/cm3. Maximum producible blank size: 4400x 1450x 900mm.

Roasting workshop: It has 5 production lines, adopts automatic roasting control system and uses natural gas for heating.

Impregnation workshop: a necessary process for enhancing the performance of graphitized carbon blocks and producing graphite electrode products.

Graphitization workshop: advanced internal heat series-connected straight furnace is adopted, and the resistance of graphitized products can be controlled ≤ 12µΩ m; The resistance of graphite electrode products can be controlled ≤ 8µΩ m.

Machining workshop: CNC assembly line combined milling machine unit is adopted, and the accuracy can be controlled within ± 0.5mm.

Electrode processing machine tools: the following facilities and equipment are mainly used for the processing of large-size graphite electrodes. In 2022, the equipment will be upgraded and transformed, and new machine tools will be introduced, which can process the largest graphite electrodes in China, and have professional graphite electrode drilling and drilling machines, which can drill and bond according to different needs of customers.

Technical advantages: The company has a full process production line for raw material calcination, mixing and shaping, roasting, billet processing, impregnation and secondary roasting, and casting of pig iron; We have three production lines with the largest specifications for molding; The first fully automated CNC machine tool in China, and the largest single graphite production line in China.

After years of research and development, the company has optimized its formula and process technology, and pioneered the two-step calcination technology of petroleum coke using imported high-quality raw materials. This greatly improves the bulk density, compressive strength, and wear resistance of graphitized cathode carbon blocks, achieving a bulk density of>1.68g/am3 for the first baked product; Maintain its resistivity<1142 · m and achieve international leading technical indicators.

While reducing the energy consumption of aluminum electrolysis cells, it is also beneficial for extending the lifespan of aluminum electrolysis cells. The development of this technology not only meets the goal of reducing the comprehensive AC power consumption per ton of electrolytic aluminum by 13300 kWh or less by 2025, but also extends the lifespan of aluminum electrolytic cells.

Tag:

Product inquiry

Filling in your phone and E-mail information will help us to get in touch with you in time and solve your problems as soon as possible.